Equipment

Our equipment can be applied in several industries, from chemical, pharmaceutical to food industries and energy too. Our team assures the design, sizing, construction and material selection according to the requirement of each project. We assure the resistance to corrosion and high temperatures.

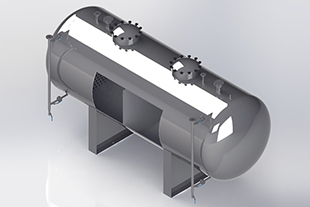

PRESSURE VESSEL AND REACTOR

Pressure Vessel or Reactor are vessels that work at pressures above 0.5 bar. These vessels are built according to the European Pressure Equipment Directive directive (PED 2014/68/EU) or American Boiler and Pressure Vessel Code (ASME BPVC), with specifications according to pressure, temperature (with heating and/or cooling), agitation, and others.

TANK STIRRER

Tanks with agitators are designed to increase the process efficiency. They serve to mix, dissolve, stir or homogenize liquid products. The size of these devices is designed according to the densities and viscosities of solutions of each industrial process, with solutions for any scenario, including vertical, horizontal, lateral, or even bottom magnetic stirrer.

SHELL AND TUBE HEAT EXCHANGERS

A shell and tube heat exchanger is the most common type of heat exchanger , used in all applications from oil refineries, chemical processes, and it is well suited for higher-pressure applications. We design and build any type of S&T heat exchanger, including straight (single or dual pass), U type, with TEMA-standard parts.