Ultrasonic Reactors

IncBio has conducted extensive R&D in ultrasonic reactor technology, and after a considerably long time spent in testing a variety of feedstocks and processes we have developed our own reactors specifically for industrial processes, on both batch and continuous plants. These ultrasonic reactors can be fully ATEX compliant and can be retrofitted to any operational plant.

By creating molecular cavitation our reactors ensure that whenever a process requires intensive mixing, the medium is homogeneously emulsified and come to a complete reaction, increasing yields dramatically.

Ultrasonic Cavitation

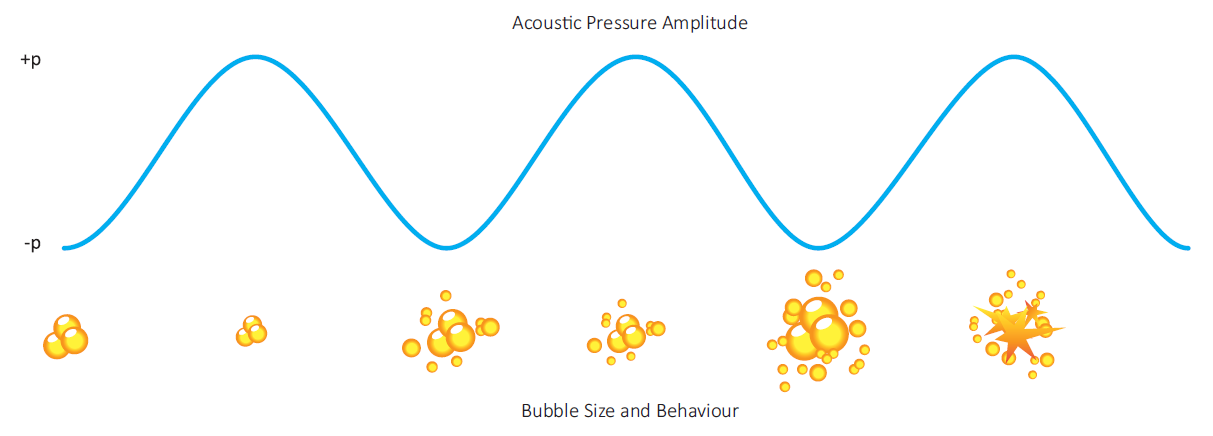

Ultrasound is transmitted through a medium via pressure waves by inducing vibrational motion of the molecules which alternately compress and stretch the molecular structure of the medium due to a time-varying pressure.

Therefore, the distances among the molecules vary as the molecules oscillate around their mean position. If the intensity of ultrasound in a liquid is increased, a point is reached at which the intramolecular forces are not able to hold the molecular structure intact.

When the bubbles attain a volume at which they can no longer absorb energy, they collapse violently during a high pressure cycle. This phenomenon is termed cavitation.

The high collapse temperatures and high‐energy particle collisions are responsible for thermal emission. It is estimated that the temperatures inside a collapsing bubble may reach 5,000 K, with pressures in excess of 1000 atm.

Emulsion

Ultrasound is used in a wide range of physical, chemical and biological processes. Emulsion and dispersion are two physical processes examples.

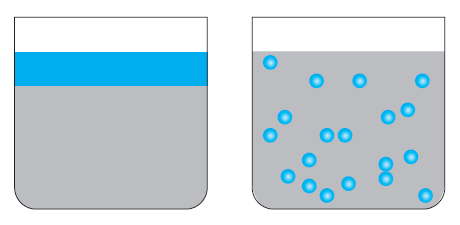

Emulsification is a process of mixing two or more immiscible liquids, which result in heterogeneous systems, consisting of at least one immiscible liquid intimately dispersed in another in the form of droplets.

Cavitation bubble collapse at or near the interface between the two liquids, causing disruption and a very efficient mixing. Ultrasonically generated emulsions are often more stable and require less, if any surfactant than those produced conventionally.

Since ultrasound is fully controllable and adaptable by the choice of amplitude, pressure and temperature.

Dispersion

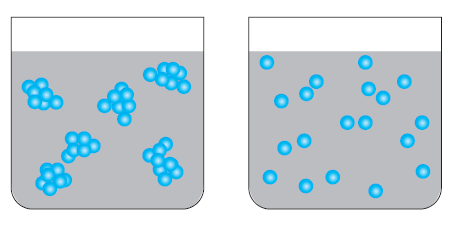

Dispersion, is a consequence of micro turbulences caused by fluctuation of pressure and cavitation. Investigations at different materials, have demonstrated the considerable advantage of ultrasound when compared with other technologies In particular for small matter from several nanometers to couple of microns, ultrasonic cavitation is very effective in breaking agglomerates, aggregates and even primaries.

When ultrasound is being used for the milling of high concentration batches, the liquid jets streams resulting from ultrasonic cavitation, make the particles collide with each other at velocities of up to 1000km/h.

This breaks van der Waals forces in agglomerates and even primary particles. Large particles are subject to surface erosion (via cavitation collapse in the surrounding liquid) or particle size reduction (due to fission through interparticle collision or the collapse of cavitation bubbles formed on the surface).

For each specific application and process there is a specific optimal parameter configuration. Most important are amplitude, pressure, temperature and viscosity.

Amplitude

The amplitude of oscillation describes the way the sonotrode surface travels in a given time (e.g. 1/20,000s at 20kHz). The larger the amplitude, the higher is the rate at which the pressure lowers and increases at each stroke. In addition to that, the volume displacement of each stroke increases resulting in a larger cavitation volume (bubble size and/or number). When applied to dispersions, higher amplitudes show a higher destructiveness to solid particles.

Pressure

Elevated pressure allows cavitation at temperatures close to or above the boiling point. It also increases the intensity of the implosion, which is related to the difference between the static pressure and the vapor pressure inside the bubble. Since the ultrasonic power and intensity changes quickly with changes in pressure, a constant-pressure pump is preferable. When supplying liquid to a flow-cell the pump should be capable of handling the specific liquid flow at suitable pressures.

Temperature

High temperatures helps to disrupt strong solute–matrix interactions. But, on the other hand, cavitation is better attained at lower temperatures when the ultrasonic power of the generator is constant. This is because as the temperature of the solvent rises so does its vapor pressure and so more solvent vapor fills the cavitation bubbles, which then tend to collapse less violently, that is, the sonication effects are less intense than expected.

Viscosity

Viscosity is a qualitative measure of molecular interaction in a liquid. The higher the viscosity, the higher the attractive forces between the molecules and, therefore, the higher the threshold intensity of ultrasound for the onset of cavitation.

Contact us today with your enquiry