Ultrasonic Extraction of Edible Oils

Edible oils, from the more usual corn oil or soybean oil, to olive oil, or the more refined avocado or hemp seed oil, are used for many applications, from cooking and food production, to oleochemicals.

From an extraction point of view, the best option to prevent oil degradation, is to perform a mechanical extraction.

Ultrasonic extraction of edible oils is equivalent to a mechanical extraction, as it is a non-thermal technique. Most importantly, although not creating any degradation, it produces high quality oils, faster and with higher yields than non-ultrasonic mechanical processes.

Ultrasonic cavitation is an highly efficient method of disrupting cell walls, and releasing plant material. The sheer force of the ultrasonic cavitation ensures that release, maximizing the efficiency of the solvent, and in some cases, avoiding solvent altogether.

Any type of vegetable oil extraction can benefit from these improvements, from extra virgin olive oil, avocado oil, sunflower seed oil, flaxseed oil, even palm oil or coconut oil.

Advantages of Ultrasonic Extraction of Vegetable Oils

- Higher yield than traditional mechanical extraction

- Reduction in processing time

- Reduction in solvent use, or no solvent at all!

- No heating required

- Improvement in nutrient quality

Contact us today with your enquiry or any questions, regarding extra virgin olive oil extraction, avocado oil extraction, or any other application for vegetable oil extraction.

High-Performance food grade Ultrasonic Reactors

With a long experience in industrial processing plants, IncBio Ultrasonic Reactors allow for a continuous operation 24/7, with highly efficient flow through design, or batch design, depending on feedstock type and production capacity.

The plug-in design allows to easily integrate in an existing plant, with minimal changes to the exiting process.

Ultrasonic Reactors

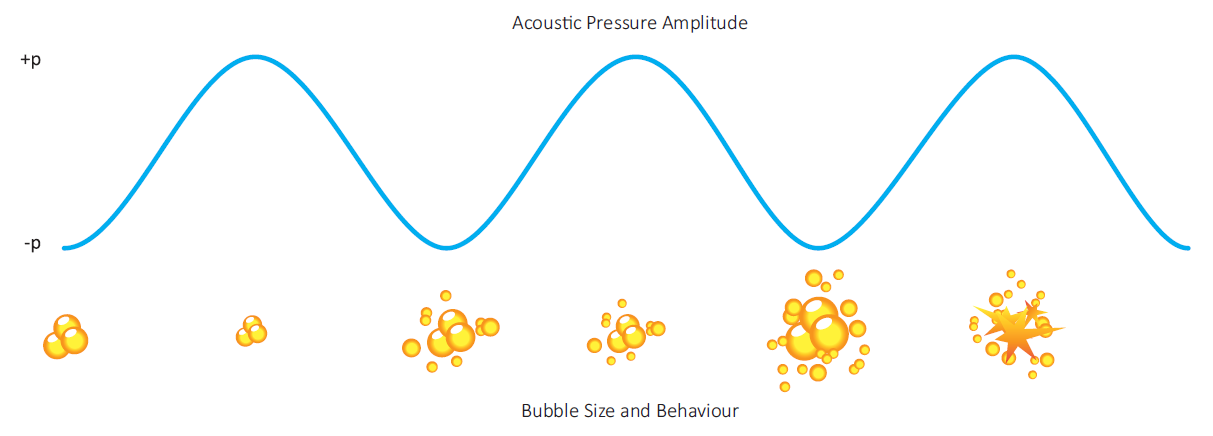

When sonicating liquids at high intensities, the sound waves that propagate into the liquid media result in alternating high-pressure (compression) and low-pressure (rarefaction) cycles, with rates depending on the frequency. During the low-pressure cycle, high-intensity ultrasonic waves create small vacuum bubbles or voids in the liquid. When the bubbles attain a volume at which they can no longer absorb energy, they collapse violently during a high-pressure cycle.

This phenomenon is called cavitation. During the implosion very high temperatures (approx. 5,000K) and pressures (approx. 2,000atm) are reached locally. The implosion of the cavitation bubble also results in liquid jets of up to 280m/s velocity.

Ultrasound has been proven to generate very homogenous emulsions by the high cavitational shear. As the parameters of ultrasonication are fine-tuned, particle size and distribution is well adjustable and repeatable.

Contact us today with your enquiry